Author: Rihab ABBA

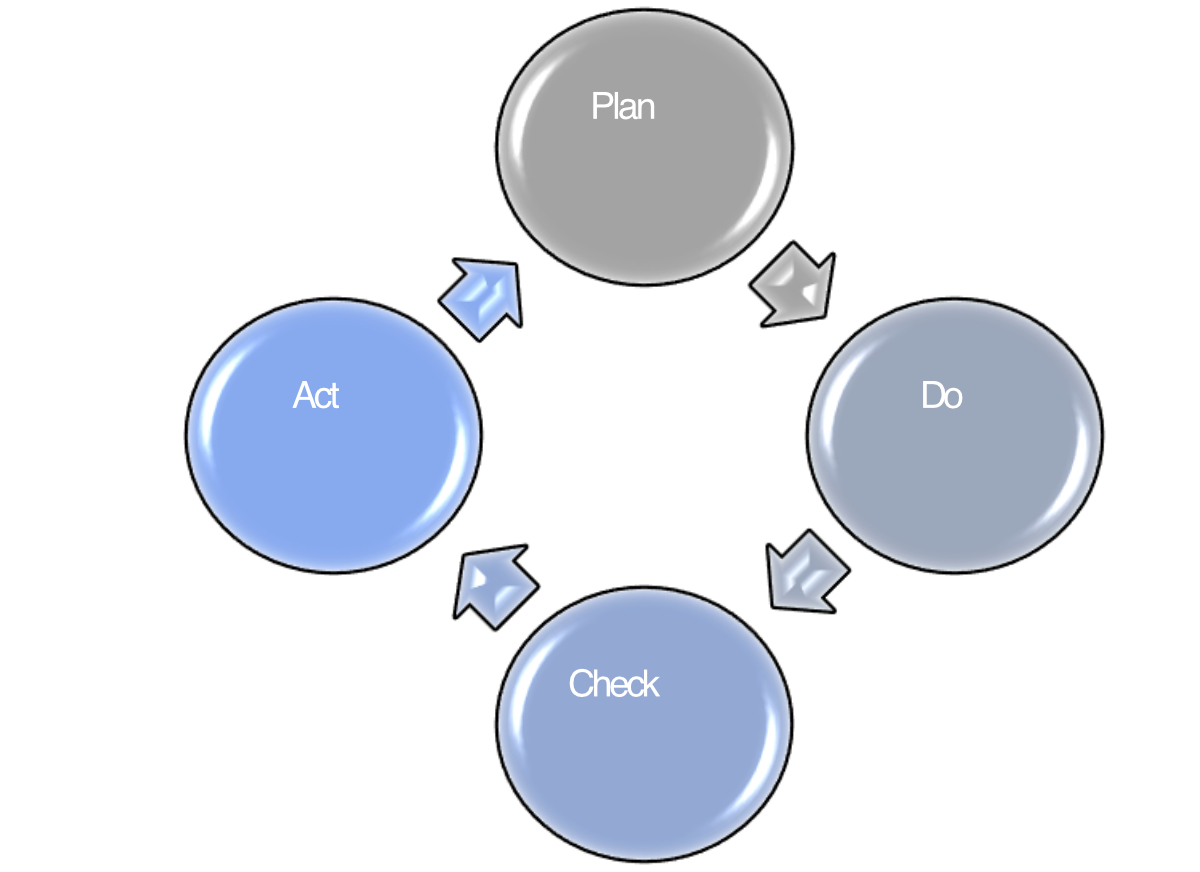

When solving problems on a daily basis, managers often lack time to explore new methods, and are grateful for proven techniques. Why should they attempt to reinvent the wheel? Speaking of which, the Deming Wheel is one of the most acclaimed approaches, tested and validated by the biggest organizations around the planet for the past 70 years. It was named after its inventor, Dr. W. Edwards Deming, a quality control pioneer and management consultant who presented this method during a lecture in Japan in 1950. He was unaware that his idea was about to revolutionize the way processes and products were improved. The Deming wheel, or Deming Cycle, is better known under the acronym PDCA, which stands for Plan – Do – Check – Act. These four action verbs refer to the four steps of the approach:

-

- PLAN: Define the problem by identifying its nature and its impact. Describe current performances and set a SMART goal (Specific, Measurable, Achievable, Relevant and Time-bound). Assess the gap between the current achievements and the desired ones. This step requires data collection for a better understanding of the processes to improve. When the present and target situations are clearly outlined, the manager moves to the next step.

-

- DO: List potential solutions to reach the goal and test them out. It is best done in a team, as each team member could investigate one or more options and apply them on a small scale.

-

- CHECK: Evaluate outcomes from step DO: How did the pilot solutions work out? Was any of the options successful? Did we manage to reach the desired situation on the sample process or project? Which of the options worked better? Do we need to combine two or more of them to meet our goals? This step is a decision point in the PDCA approach. As long as the results are not conclusive, the team can’t move to the next step and goes back to the DO step to discuss additional options or combinations, then runs another CHECK. They carry out a to and fro between negative checks and new rounds of DO, until a CHECK comes out positive. In desperate cases, the initial PLAN is reassessed, and the goal is reviewed.

-

- ACT: the successfully tested option is now implemented on a larger scale to improve the process as a whole and achieve the initial goal. Once this is done, the team is ready to plan the next cycle, but this time the current situation is updated and new goals are set.

In daily life, the PDCA approach comes with a few limitations, as it can’t be used in case of real emergencies, where there is no room for testing and re-testing. Another weakness of the approach stems from its very simplified steps, which could sometimes be considered as over- simplification. This is due to the absence of guidance on how to manage relationships between peers and with hierarchy during the problem-solving process, especially when it comes to identifying team members, validating options and rewarding the effort. Nonetheless, PDCA is quite popular, namely because it mimics scientific methods by testing solutions and confirming their efficiency before applying them on the entire process to be improved. So the risk of implementing a sub-optimal solution is low, and the cost of error is reduced. Think of it in laundry terms: if your new favorite apparel needs cleaning and you’re not sure about the product to use, it’s safer to test various methods on hidden areas of the piece of clothing to minimize errors’ impact, before applying the most effective solution on the entire garment.

Beside cost-effectiveness and risk management, PDCA is a simple tool for organizations in highly competitive environments, as the continuous improvement is standardized. Accessibility is another of PDCA’s strong points: it can be used at all management levels, by individuals as well as teams and departments. Several major companies incorporate it into their culture (Toyota, Nike, Nestlé...) for streamlining processes, particularly in speed-and- goal driven industries. It is also valuable in startups and SMEs where flexibility and cost control are competitive assets.

#Management_problems #esca_ecole_de_management #problem_solving #pdca #six_sigma #g8d #probelm_solving_approaches

.png)